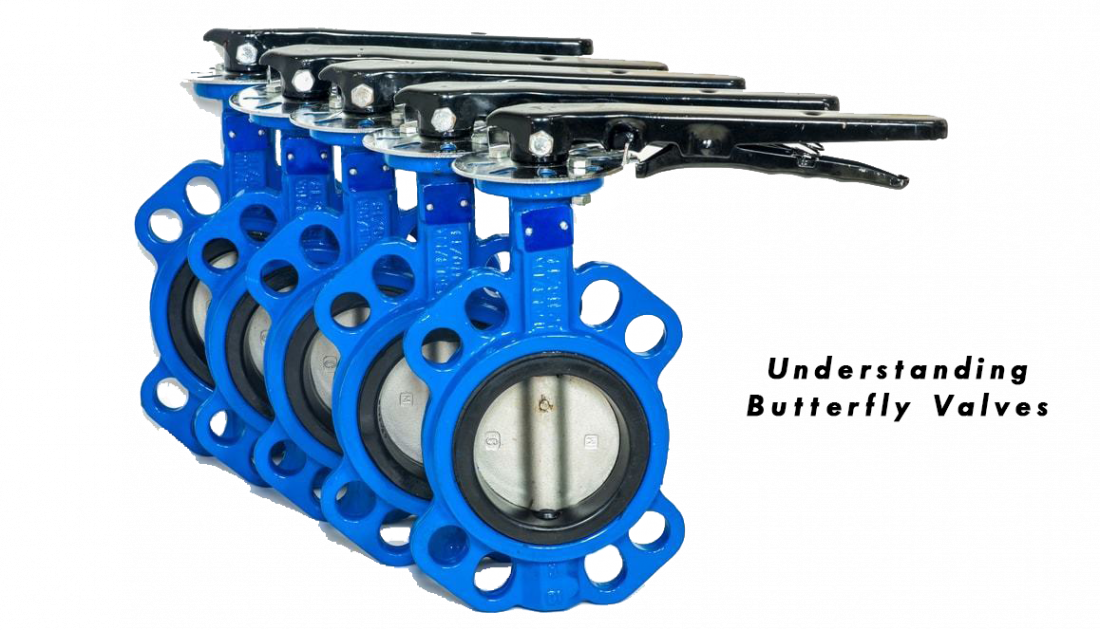

Butterfly valves are quarter-turn valves used to stop, regulate, start and throttle flow. In general, the butterfly valve is used for handling large volumes of fluid with its fairly tight seals that control the flow sharply. For some time butterfly manufacturers have incorporated several features to extend their operational capabilities.

Earlier, butterfly valves were used in low-pressure applications. They were preferred because of their lightweight and space-saving characteristics. To enhance the functionality of butterfly valve manufacturers in India, have made distinct modifications in the mechanism of the butterfly valve to get better results.

Butterfly manufacturers in India have categorized the Butterfly valve prices based on their dimensions and the material used for manufacturing. There are several types of butterfly valves available that can be selected as per your requirement.

Butterfly Valve Types

Butterfly valve types can be categorized into the following types:

- Wafer Type Butterfly Valve

- Lug Type Butterfly Valve

Wafer Types

The body of the wafer-type butterfly valve is placed between pipe flanges, and the flange bolts surround the valve body. Installation of a wafer-type butterfly valve is easy but it cannot be used as an isolation valve.

Lug Type Butterfly Valve

The lug-type butterfly valve body has protruding lugs surrounding the body. It provides passage to bolt holes that match with those in the flanges.

Different Types Of Butterfly Valve

Except for wafer type butterfly valve and the lug-type butterfly valve, there are different types of valves manufactured and supplied by butterfly manufacturers in India. The butterfly valves differ from each other in terms of mechanism and the materials used to manufacture them. The different types of butterfly valves on the basis of the materials are,

- Aluminum Butterfly Valve

- Cast Iron Butterfly Valve

- Cast Steel Butterfly Valve

- Ductile Iron Butterfly Valve

- PP Butterfly Valve

- SG Iron Butterfly Valve

- Stainless Steel Butterfly Valve

- Stainless Steel Butterfly Valve- Commercial Casting Size

Functions Of Butterfly Valve

Butterfly valve supplier gives considerable focus on the functionality and performance of butterfly valves, to give the desirable and anticipated result to the users.

The predominant functions of the butterfly valves are:

1.Flow Regulation

2.Flow Isolation

3.Prevention Of Backflow

Application Of Butterfly Valve

Following is the list of industries that uses butterfly valve for industrial processes,

- Aerospace Sectors

- Corrosive Processing

- Vacuum Service

- HVAC

- District Heating, Mining, and Shipyards

- Lubrication

- Petroleum Industries

- Refrigeration and Air Conditioning

- Petroleum Industries

- Irrigation and Agricultural Needs

- Slurry Application

- Compressed Air Applications

- Wastewater Treatment

- Gas Application

- Sanitary Valve Applications

- Compressed Air Applications

- Sprinkler Valve Applications

- High-pressure and High-Temperature water and steam services

Butterfly valve suppliers understand the vitality of the valve and hence they keep the manufacturing standards high concerning the quality, durability, and performance.

Butterfly valve suppliers in India cater to a wide range of markets due to the wide application and usage of a butterfly valve in different industries. Butterfly valves can be used for different purposes and industries.

In general, butterfly valves are suitable for,

- Throttling valves

- Constant Load Applications

- Space-restrictive Applications

Advantages of Butterfly Valve

Butterfly valve suppliers have understood the importance and advantages of butterfly valves and their huge market demand. Butterfly valve provides following advantages,

- Compact design- lessens space requirement

- Lightweight- easy for the piping system to accommodate it

- Quick operation; less time required for opening and closing

- Easy Installation

- Simple operation due to low operation torque

- Available in very large sizes and small sizes

- Improved energy efficiency

- Low-pressure drop and high-pressure recovery

- Durability

- Relatively pocket friendly

- Less number of parts; that required negligible maintenance

Components Of Butterfly Valve

The butterfly valve though being multi-tasking comprises only 4 main body components that constitute the butterfly valve.

1.Butterfly valve body

2.Butterfly Valve Disk

3.Butterfly Valve Stem

4.Butterfly Valve Seat

Conclusion

For handling large volume capacities butterfly valves are used. It can be used to control flow, regulation, and shut down or open the medium. With research and modifications by butterfly valve manufacturers in India and butterfly valve suppliers in India, developments have permitted this type of valve to throttle more accurately and perform well in high-temperature and high-pressure applications. While installing the butterfly valves, despite their usage as isolation valves, the piping system should be carefully designed to eliminate system losses.

Butterfly valves are economic and reliable for high-performance with less maintenance and easy installation in various industries.

Validate your login