A ball valve gets operated using a rotary ball having a bore to control and shut off the flow of liquid or gas. The medium flowing through the pipe can be allowed to flow or block by rotating the ball a quarter-turn, that is at 90 degrees. Ball valves provide a long service life and reliable sealing over the lifespan.

They are designed with special measures permitting only a 90-degree rotation to open and close the ball valves. These valves are a notable industrial choice because of their reliable and air-tight sealing.

The ball valve works efficiently even after not being used for a long time, this characteristic of the ball valve makes it widely used and a popular shut-off valve to control and block the flow in the pipeline. Moreover, ball valves are more resistant to contaminated media than most other types of valves.

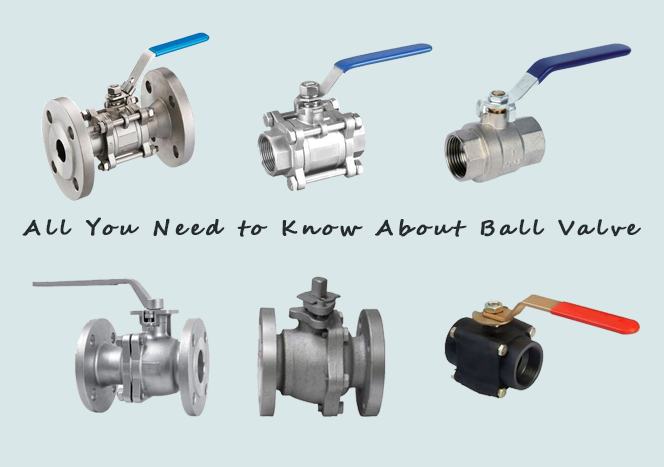

Common Ball Valve Types

- Standard (Threaded)

- Hydraulic

- Flanged

- Vented

Ball valve types can also be classified based on metal and materials used to manufacture it as well as the dimensions and sizes. Ball valves are available in different sizes and dimensions to cater to different industries and purposes.

Ball valve types based on the materials can be further classified into the following types,

- Mild Steel Ball Valve

- Iron Ball Valve

- Brass Ball Valve

- Stainless Steel Ball Valve

- PP Ball Valve

- Forged Carbon Steel Ball Valve

Uses of Ball Valve

Ball valves are used in many different industries and hydrocarbon process applications. It is used in residential buildings too.

They are capable of throttling gases and vapors, especially useful for low-flow situations. These valves provide quick opening and a very tight closure on hard-to-hold fluids, making it a widely used and accepted control valve. Ball Valves, used for flow control and whenever tight shut-off is required.

Ball valves are used in,

- Oil and Natural Gas Industry

- Manufacturing Sectors

- Chemical Storage

- Residential Uses

Ball Valve Specifications

While installing or ordering the ball valves, one must go through the ball valve specifications. To get the desired results and control of the fluid or gas the ball valve must be selected keeping the required ball valve specifications in consideration.

All industrial setups and facilities have different productions, raw materials, processes that require different materials and temperature setups, to mechanize and control such materials with different temperatures, you need to install appropriate ball valve material. To select the proper required ball valve with the proper dimension to fill the factory machines and setup, one must consider the ball valve specifications to get the desired result and longevity.

Advantages Of Ball Valve

- Compact and low-maintenance design

- Requires no lubrication

- Cost-effective among all of the valves

- Leak-proof service

- Open and close quickly

- Ball valves have multi-way design flexibility

If you are looking for a ball valve manufacturer in Ahmedabad or a ball valve supplier to get the best quality ball valve with different specifications having to vary with metals and dimensions, for any kind of use or installation, visit indusroof.com and order the ball valves as per your requirement. The price list of the ball valve is mentioned in our online store, the price list of the ball valve in India varies as per the materials used in the ball valve as well as the dimensions of the ball valve.

Validate your login