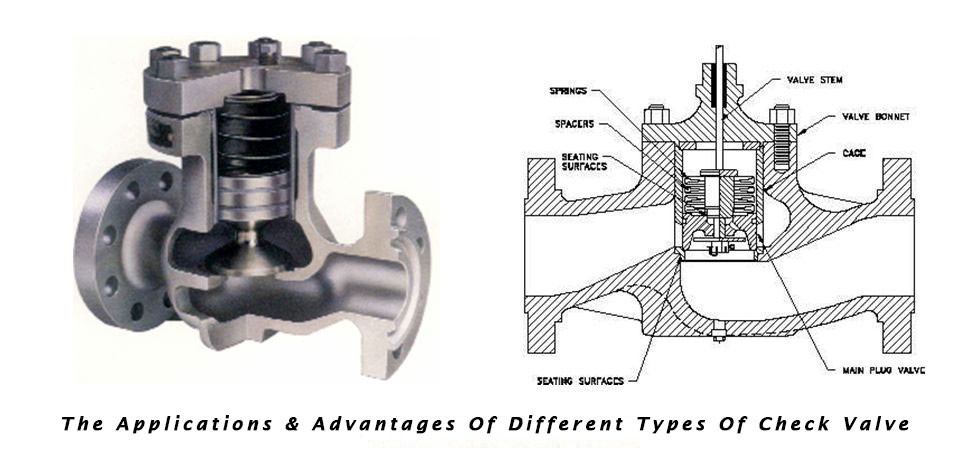

A check valve is a widely used valve in different sectors and installments ranging from domestic usage to industrial usage. In this article, we are putting a light on detailed information about the usage, advantages, and mechanism of different types of industrial check valves. First of all, let's have an introduction to check valves.

What Is A Check Valve?

A check valve is an automatic shut-off valve, designed to allow the flow of fluids and gases in a single direction.

The check valves operate under pressure and flow; the closure mechanism opens allowing the gases or fluids to flow freely.

Fluids or gas enter the valve at the inlet and exit through the outlet. Until the pressure drops, or the pump is shut down the flow continues without any interruption.

It is one of the few self-automated valves that don’t require assistance to open and close, unlike other valves. If the plant facility loses air, electricity, or labor assistance it won't affect the work continuity of the valve.

PVC check valves are widely used by various industries. Check valves are ideal for water pumps.

Mechanism Of Check Valve

The industrial check valve gets activated by the flowing material. The check valve will get opened automatically by the pressure of the material passing in the right direction and if the flow gets reversed, then the valve closes automatically.

While getting opened the internal disc in the valve allows the flow to pass forward. The disc begins closing the valve as forward flow gets decreased or is reversed.

Parts Of Check Valve

- Cover

- Body

- Flange

- Hinge Pin

- Seat

- Disk

- Hinge Arm

Types Of Check Valve

- PVC Check Valve

- Dual Plate Check Valve

- Swing Check Valve

- Wafer Type Check Valve

- Ball Check Valve

- Lift Check Valve

- Stainless Steel Valve

- Feed Check Valve

- Reflux Valve

- Brass Check Valve

- Cast Iron Check Valve

- Stainless Steel Check Valve

- Cast Steel Check Valves

Application Of Check Valve

The application and usage of check valves range from domestic to industrial purposes. Check valves can be used in the following sectors and systems,

- Pumping Systems

- Pipeline Networks

- To Control Fluids

- To Control Gaseous Flow

- Pharmaceutical Factories

- Aircraft Hydraulic Systems

- Irrigation Systems

- Fuel Pump

- Water Supply Check Valves

- Heating Boilers

Advantages Of Using Check Valves

It doesn’t matter what type of check valve is getting installed. The answers to your question about why do we need a check valve to get installed are below,

- Low-Pressure Change

- Quick Opening

- Works Automatically

- Prevents Back Flow

- Do Not Require Power To Operate

- Maintains Pressure

- Low Maintenance Costs

- Serve As a Backup System

- Ideal For High And Low Pressure

- Reliable And Long Service Life

- Used For Both Horizontal And Vertical Flow

- Protect Pumps And Compressors From Damage Caused By Back Flow

- Reduce Downtime And Loss Of Production

- Prevent Water Hammer

- Reduce Sudden Valve Failure

Materials Used For Different Types Of Check Valve

Different types of check valves are required for different setups and usage. Following that, whether it is PVC Check Valve, Dual Plate Check Valve, Swing Check Valve, Wafer Type Check Valve, Ball Check Valve, or Lift Check Valve all these industrial check valves are available in different dimensions and materials. The price of check valves is quoted as per the materials used and the dimensions of a check valve.

The check valves are manufactured using PVC, stainless steel, cast iron, cast steel, bronze, and brass. The Industrial check valve price varies depending upon the types of valve, metal, and dimension.

Validate your login